Enabling multimodal AUV residency with wireless technology:

The Problem: Persistent Underwater Presence

AUV missions are limited by battery endurance and recovery cycles, creating gaps in underwater awareness and increasing operational risk for defence, security, and industrial users..

The Solution

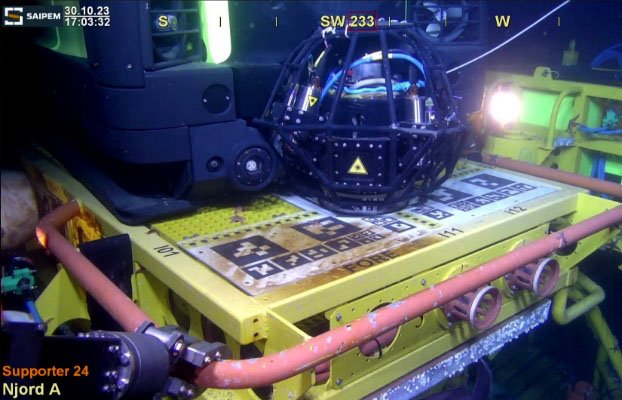

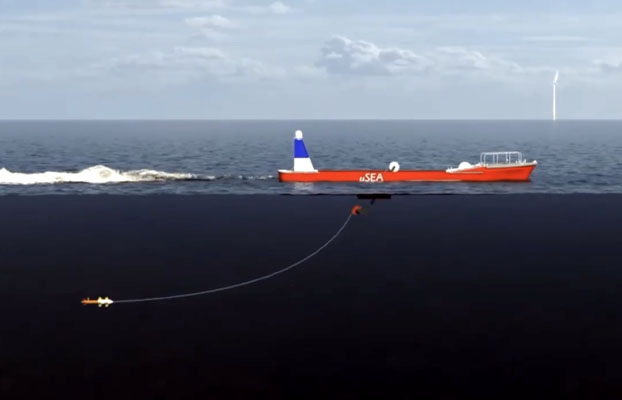

Inductive subsea docking stations that let AUVs dock, recharge, exchange data, and stay resident without surfacing. Deployable under jetties, beneath buoys, or in mobile/towed configurations.

Why It’s Different

- Works with any torpedo or flat AUV

- Supports resident, buoy-mounted, and mobile/towed concepts of operation

- 200 W–2.5 kW inductive power, roadmap to 25 kW

- 1 to 10 Gbps agreageted

- Proven subsea technology with world-record performance

- 3000 m rated, 15-year life API17 F and SWiG compliant

- Integrated inductive positioning for reliable docking in low visibility